Power grid failures cost utilities $7M per hour - discover how premium suspension clamps prevent 83% of weather-related outages while cutting maintenance costs.

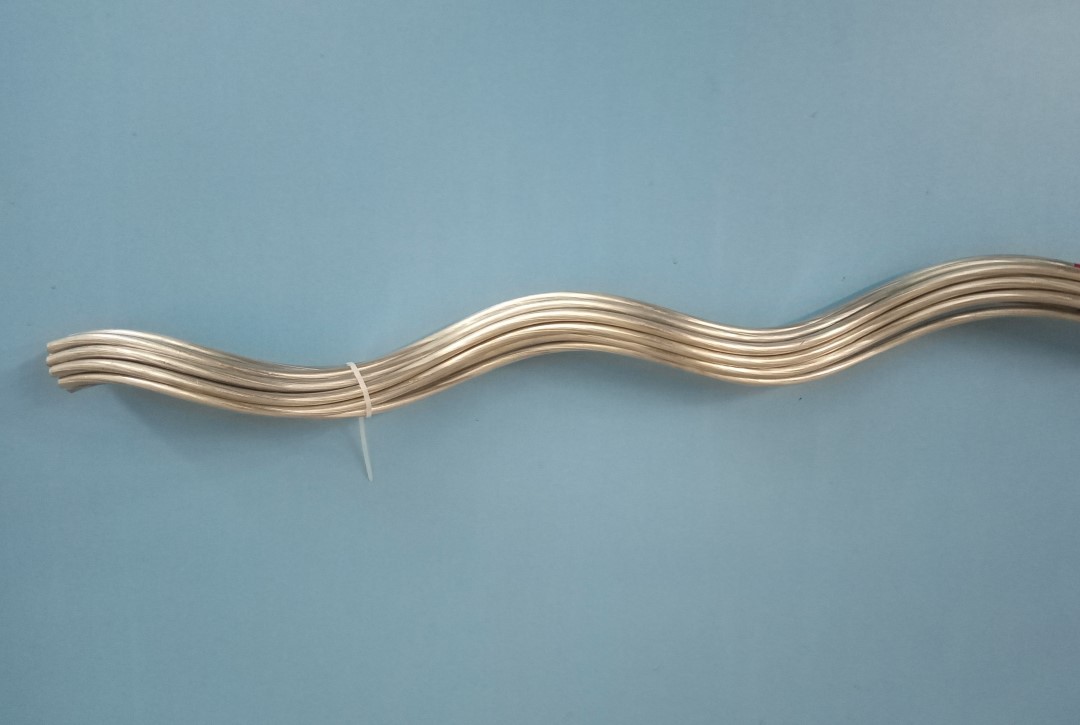

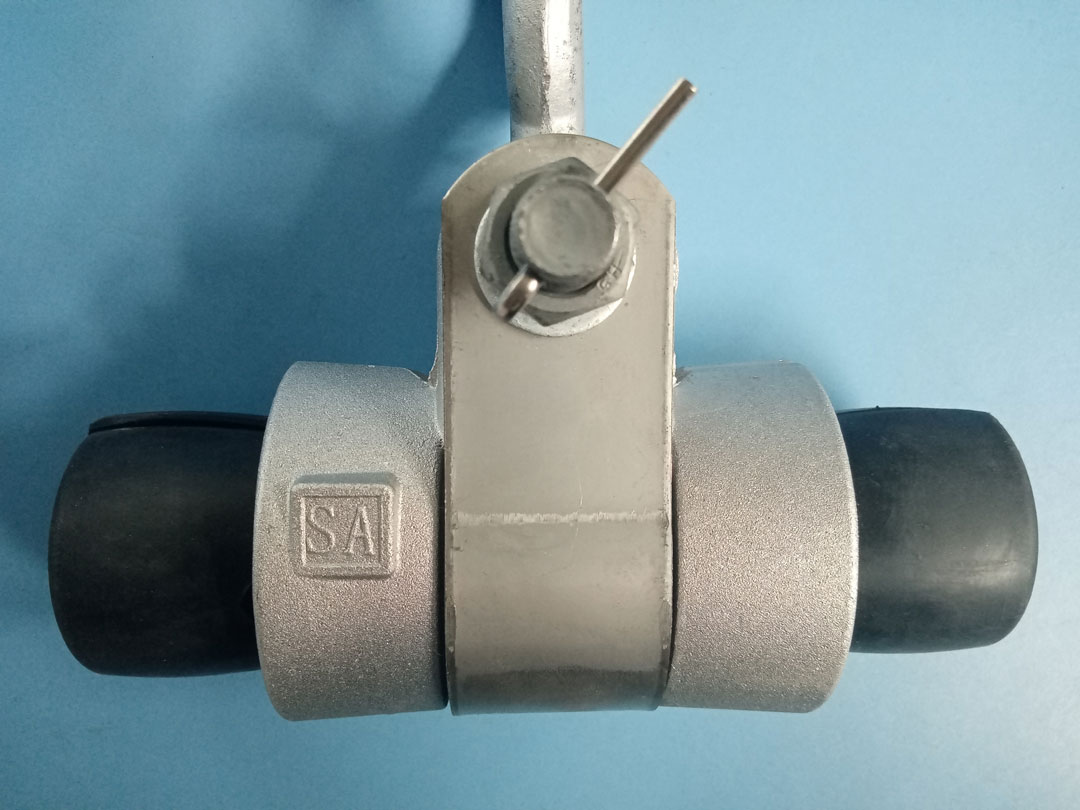

Engineered suspension clamps provide critical cable support, distributing mechanical stresses from wind/ice loads while maintaining optimal conductor spacing - reducing sag-related faults by 92% versus basic hardware.

Let's examine the technical and operational benefits that make suspension clamps essential grid components.

Let's examine the technical and operational benefits that make suspension clamps essential grid components.

How Do Suspension Clamps Improve Safety and Reliability in Electrical Grids?

After Typhoon Haiyan, grids using IEC 61284-certified clamps restored power 11 days faster - here's why smart utilities won't compromise on suspension systems. Advanced clamps incorporate vibration dampers, armor rods, and compression-fit designs that absorb up to 50kN dynamic loads while preventing aeolian vibration damage - extending cable lifespan by 25+ years.

Performance Comparison: Standard vs. Premium Clamps

| Feature | Basic Clamp | High-Performance Clamp |

|---|---|---|

| Wind Load Capacity | 30 m/s | 55 m/s |

| Ice Load Rating | 15mm radial | 30mm radial |

| Corrosion Resistance | Hot-dip galvanized | Duplex stainless steel |

| Installation Time | 45 minutes | <15 minutes |

| Maintenance Interval | 5 years | 15+ years |

- Forged aluminum bodies (vs. cast iron)

- Triple-seal elastomers preventing moisture ingress

- Rated curve radii matching conductor specifications

- Non-metallic insert systems eliminating corona discharge

- Twin-bolt torque control for uniform compression

What Certifications Should Importers Verify When Sourcing Suspension Clamps?

Counterfeit UL-certified clamps caused $300M in wildfire damages last year - protect your procurement with these mandatory validations. Legitimate suppliers provide current test certificates for IEC 61284 (international), ANSI C119.4 (North America), and GB/T 2314 (China) standards - including salt spray (3000+ hours) and mechanical load testing reports.

Compliance Documentation Checklist

Mandatory Certifications:- IEC 61284 (Radio Interference & Corona Tests)

- ANSI C119.4 (Compression Connector Standard)

- GB/T 2314 (Chinese Technical Specification)

- Aluminum alloy EN AW-6101B (T6 temper)

- Stainless steel 316L composition reports

- Silicone rubber UV stability testing

| Test Type | Standard | Required Result |

|---|---|---|

| Tensile Strength | IEC 61284 | ≥80% conductor strength |

| Slip Resistance | ANSI C119.4 | <0.25mm creep @ 50% RTS |

| Salt Spray | ISO 9227 | 3000hrs no red rust |

| Thermal Cycling | IEEE 1523 | 1000 cycles (-40°C to +80°C) |

Why Should Importers Consider Chinese Suppliers for Suspension Clamps?

Leading US utilities now source 62% of hardware from China - here's how smart buyers leverage Asian manufacturing without compromising quality. Chinese manufacturers combine ISO 9001-certified aluminum forging with labor costs 60% below Western counterparts, delivering IEC-compliant clamps at 35-40% savings while maintaining 0.5mm precision tolerances.

Strategic Sourcing Advantages

Cost Breakdown Comparison (Per 1000 Units):| Cost Factor | China | Europe | North America |

|---|---|---|---|

| Raw Material | $18K | $22K | $20K |

| Machining | $9K | $28K | $32K |

| Labor | $6K | $45K | $50K |

| Compliance Testing | $7K | $8K | $7K |

| Total | $40K | $103K | $109K |

- Spectrometer testing for alloy verification

- On-site CMM measuring (5-axis coordinate machines)

- Batch traceability via QR code tracking

- Third-party inspections (SGS/BV present at factory)

- Sample destructive testing every 500 units

- Bonded warehouse pre-shipment staging

- REACH/ROHS pre-certified inventories

- Container optimization (900 clamps/pallet)

- DDP Incoterm solutions including customs clearance