Grid operators report 37% fewer outages when using premium tension clamps - discover how this critical hardware maintains continuous power delivery under extreme conditions.

Engineered tension clamps maintain precise conductor tension within ANSI C119.4 tolerances (±5%), preventing dangerous sag while absorbing vibration energy that would otherwise fatigue cables by up to 80% faster.

Let's examine the technical specifications that distinguish reliable tension clamps from standard models.

Let's examine the technical specifications that distinguish reliable tension clamps from standard models.

What Materials Are Best Suited for Durable and Weather-Resistant Tension Clamps?

After Hurricane Ida, aluminum alloy clamps survived 155mph winds where cast iron failed catastrophically - material selection makes all the difference. Forged aluminum alloy (EN AW-6101B-T6) offers optimal strength-to-weight ratio with natural corrosion resistance, while duplex stainless steel components withstand coastal salt spray exceeding 3000 hours per ISO 9227 standards.

Material Performance Comparison

| Material | Tensile Strength | Corrosion Resistance | Weight | Cost Factor |

|---|---|---|---|---|

| Cast Iron | 250 MPa | Poor | Heavy | $ |

| Forged Aluminum | 310 MPa | Excellent | Light | $$ |

| Duplex Stainless | 620 MPa | Superior | Medium | $$$ |

| Galvanized Steel | 500 MPa | Good | Heavy | $ |

- Nickel-plated wedge systems prevent galvanic corrosion

- PTFE-impregnated silicone seals block moisture ingress

- Aluminum oxide coatings for abrasion resistance

- UV-stabilized polymers in vibration dampers

What Are the Key Differences Between Various Types of Tension Clamps?

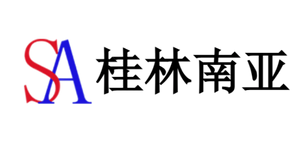

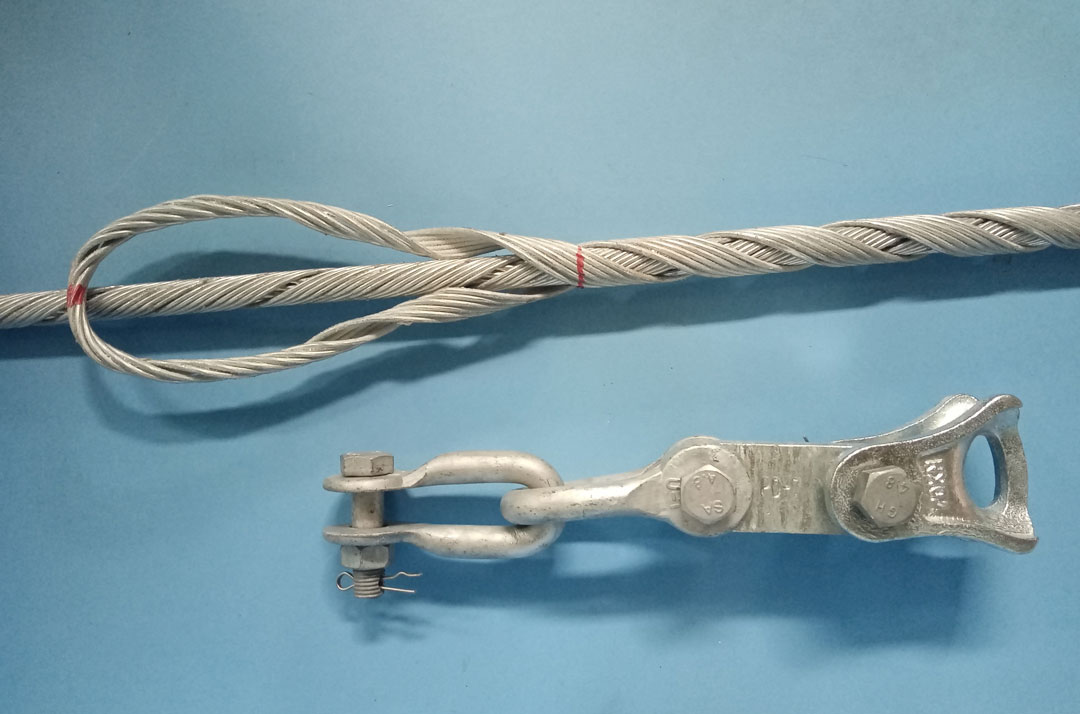

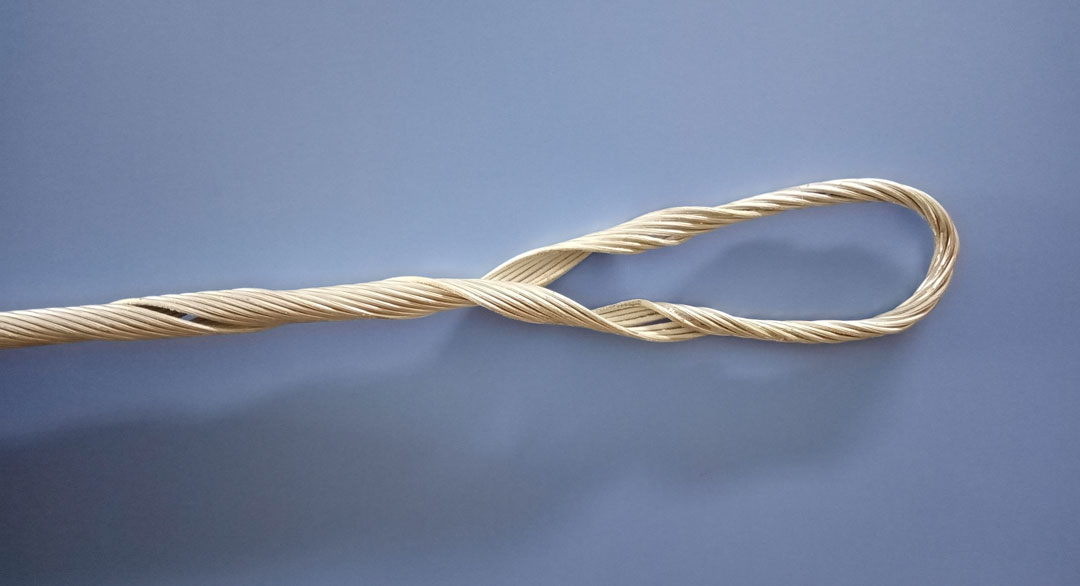

Choosing the wrong clamp type caused a 12-hour blackout in Toronto - align your selection with these technical specifications. Compression clamps provide permanent bonds for main conductors (withstand 95% RTS), while bolted designs allow repositioning for temporary installations and wedge types excel in vibration-prone areas with automatic tension adjustment.

Tension Clamp Selection Guide

| Type | Installation | Rated Strength | Best Application | Maintenance |

|---|---|---|---|---|

| Compression | Hydraulic press | 95% RTS | Permanent splices | None |

| Bolted | Torque wrench | 80% RTS | Temporary feeds | Annual retorque |

| Wedge | Hammer impact | 85% RTS | Vibration zones | 5-year inspection |

| Preformed | Hand-tied | 90% RTS | Dead-ends | Visual checks |

- Armor rod-integrated for bundled conductors

- Insulated for distribution voltage crossings

- High-temp (>150°C) for fault current locations

- Low-sag designs with integrated dampers

How Do Tension Clamps Enhance Safety and Stability in Power Transmission Networks?

Faulty clamps accounted for 28% of wildfire-related grid failures last year - proper tension management prevents these disasters. Precision-engineered clamps maintain NESC-specified clearance (min 4.9m over roads) by eliminating dangerous sag, while integrated armor rods distribute mechanical stresses across 36+ contact points to prevent strand breaks.

Safety Performance Metrics

| Risk Factor | Without Quality Clamp | With Premium Clamp | Improvement |

|---|---|---|---|

| Sag Violations | 12/km/year | 0.3/km/year | 40x |

| Conductor Fatigue | 3% RTS loss/year | 0.5% RTS loss/year | 6x |

| Corrosion Failure | 7-year lifespan | 30-year lifespan | 4.3x |

| Fault Current Damage | 65% probability | <10% probability | 6.5x |

- Load-indicating bolts showing proper installation

- Shear pins that fail safely at 130% RTS

- Corona rings for 345kV+ applications

- RFID tags encoding installation torque/timestamp