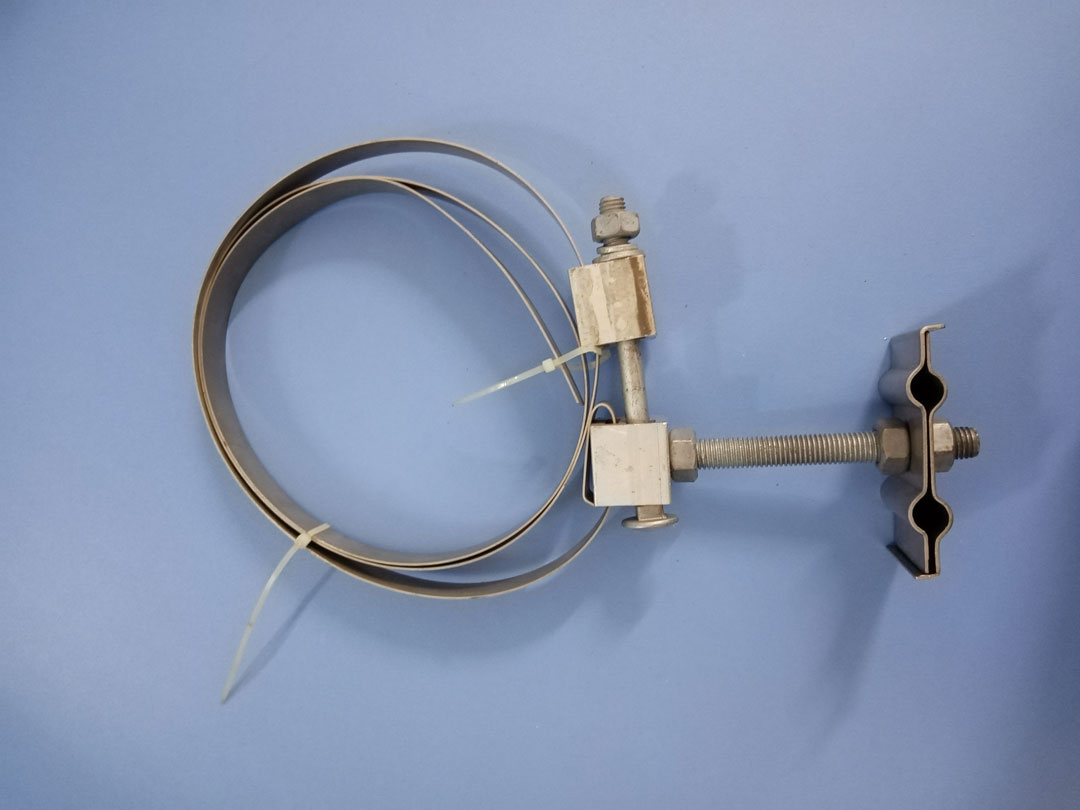

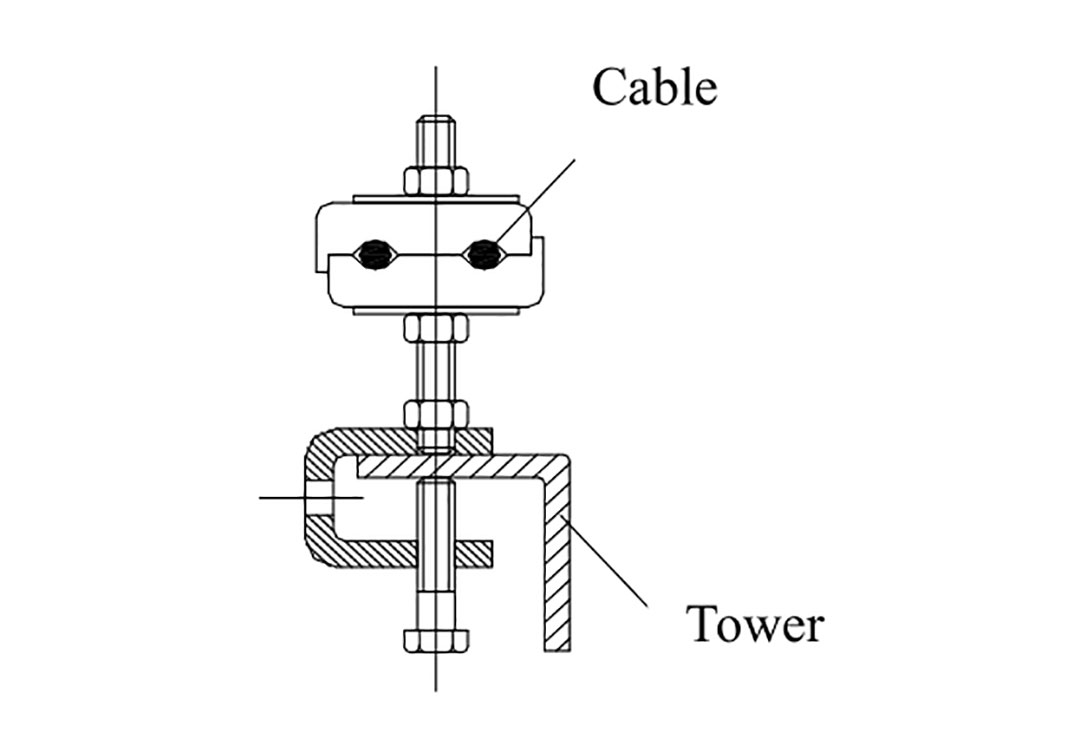

Downleading clamp failures cause 23% of preventable distribution outages - discover how this overlooked hardware prevents costly grid disruptions.

Properly engineered downleading clamps maintain NESC-mandated conductor spacing while withstanding 150km/h winds, preventing cable slap faults and reducing vegetation-caused outages by up to 65% through secure aerial-to-underground transitions.

Let's examine the technical specifications that transform simple cable holders into critical grid reliability components.

Let's examine the technical specifications that transform simple cable holders into critical grid reliability components.

How Can Importers Source High-Quality Down Leading Clamps at Competitive Prices?

Counterfeit IEC 61230-certified clamps flooded markets last year - here's how savvy buyers verify quality without overpaying. Top importers leverage batch testing (every 500 units) and on-site spectrometer validation to source ISO 9001-compliant clamps at 30-40% below Western prices while maintaining 0.1mm tolerance precision.

Strategic Procurement Checklist

| Verification Step | Cost Impact | Quality Assurance |

|---|---|---|

| Raw Material Certification | +2% | Aluminum alloy EN AW-6063 verification |

| Salt Spray Testing | +3% | 3000hrs per ISO 9227 |

| Sample Destructive Test | +1.5% | Meets IEC 61230 Clause 8 |

| Dimensional Inspection | +1% | CMM 5-axis validation |

| Production Audit | +4% | BSCI-certified factory |

- Container-load purchases (900 units/pallet)

- FOB terms with pre-shipment inspection

- Multi-year contracts locking in aluminum prices

- Dual-source agreements across 2-3 vetted suppliers

What Materials and Coatings Ensure Longevity in Down Leading Clamps?

Coastal utilities replacing clamps every 3 years switched to marine-grade alloys - now achieving 15+ year service life despite salt exposure. Duplex stainless steel (EN 1.4462) cores with fluoropolymer coatings withstand C5-M corrosion class environments, outperforming standard galvanized clamps by 8x in accelerated aging tests.

Material Performance Matrix

| Component | Premium Specification | Industry Standard | Lifespan Extension |

|---|---|---|---|

| Main Body | Forged EN AW-6063-T6 | Cast Aluminum | 3x |

| Hardware | A4 (316) Stainless | Zinc-Plated Steel | 5x |

| Seals | EPDM Rubber | NBR Rubber | 2x |

| Coating | 80μm Fluoropolymer | 15μm Anodized | 6x |

| Insulator | FRP Grade L4 | PVC | 4x |

- Sacrificial zinc anodes for cathodic protection

- Silane-based primers enhancing coating adhesion

- Chromate-free passivation meeting RoHS

- UV-stabilized polymers preventing embrittlement

Why Should Utilities Consider Chinese Manufacturers for Down Leading Clamp Supply?

70% of North American utilities now source distribution hardware from China - here's how leaders mitigate risks while capturing cost advantages. Tier-1 Chinese manufacturers combine German CNC machining (0.05mm repeatability) with labor costs 65% below Europe, delivering IEC 61230-certified clamps including full test reports at $0.38 per ampacity rating.

China Sourcing Advantage Analysis

Total Cost Comparison (Per 10,000 Units)| Cost Factor | China | Germany | USA |

|---|---|---|---|

| Material | $28K | $32K | $30K |

| Machining | $15K | $45K | $50K |

| Compliance | $7K | $9K | $8K |

| Logistics | $6K | $3K | $2K |

| Total | $56K | $89K | $90K |

- Incoming material spectrometry (PMI testing)

- Automated vision inspection (0.1mm defect detection)

- 100% load testing (1.5x rated tension)

- Sequential numbering for full traceability

- Third-party witness testing (SGS/TUV on request)